SINGLE PUSH FITTING

SINGLE PUSH FITTING Specification

- Usage & Applications

- Used in pneumatic and water systems, RO plants, air lines, and automation equipment

- Flow Rate

- Dependent on tube size; typically up to 10 bar (145 psi) and 5 L/min for 1/4 size

- Installation Type

- Push to Connect Fitting

- Surface Treatment

- No external treatment (plastic body); nickel-plated brass for inserts if present

- Connection

- Push-Fit / Quick Connect

- Technology

- One-touch push-in fitting technology

- Feature

- Reusable, leak-proof connection, easy assembly, tool-free installation

- Product Type

- Single Push Fitting

- Metals Type

- Brass (for thread insert, if any)

- Plastic Type

- Polyoxymethylene (POM) or Nylon

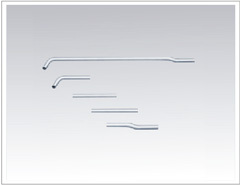

- Shape

- Straight

- Size

- 1/4 inch, 3/8 inch, 1/2 inch (various options available)

- Finish

- Smooth

- Dimensions/Size

- Varies as per selected size (e.g., 1/4 OD x 1/4)

- Color

- Black, Blue, White (Common Variants)

- Material

- Plastic Body with optional Brass/Metal Insert

SINGLE PUSH FITTING Trade Information

- Minimum Order Quantity

- 50 Pieces

- Supply Ability

- Piece

- Delivery Time

- 1 Week

About SINGLE PUSH FITTING

Versatile Material & Wide Application

Crafted with premium plastic (POM or Nylon) and optional brass inserts, the SINGLE PUSH FITTING offers distinctive durability and chemical resistance. Commonly installed inline in pneumatic circuits, water filtration systems, RO plants, and automation setups, it ensures a robust, seamless connection. Designed for quick, tool-free assembly, it suits both specific industrial needs and general applications, delivering efficient flow and reliable sealing across sites.

Swift Delivery & Trusted Certification

Benefit from prompt supply and delivery times, enhancing your projects market value and completion schedule. The SINGLE PUSH FITTING is certified to meet RoHS and REACH requirements, reassuring buyers worldwide of its premium quality. Major export markets comprise Asia and Europe, where value-driven traders, distributors, and manufacturers demand reliable, compliant products that maintain high performance throughout logistics and installation.

FAQs of SINGLE PUSH FITTING:

Q: How does the SINGLE PUSH FITTING ensure a leak-proof connection?

A: The fitting utilizes advanced one-touch push-in technology and high-quality NBR or EPDM seals, guaranteeing a reusable, leak-proof assembly without tools.Q: What is the recommended process for installing the SINGLE PUSH FITTING?

A: Simply push the tube into the fitting for quick, tool-free installation. It is designed for inline mounting in pneumatic and water systems.Q: Where can this fitting be used most effectively?

A: It is ideal for use in RO plants, water filtration systems, pneumatic air lines, and automation equipment across industrial and commercial settings.Q: When can product delivery be expected after ordering?

A: Delivery times vary by location but are typically prompt, supporting supply chain reliability and meeting deadlines for distributors and exporters.Q: What certifications does the SINGLE PUSH FITTING have?

A: It is RoHS and REACH compliant, which assures compatibility with international safety and environmental standards.Q: What is the main benefit of using this fitting in automation equipment?

A: Customers gain from tool-free installation, reusable connections, robust sealing, and adaptability to diverse tubing sizes, promoting productivity and efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Jindal cistern internal fittings Category

LLC DUAL FLUSH FITTING

Minimum Order Quantity : 50 Pieces

Connection : Push Button / Cable Mechanism

Technology : Dual Flush Mechanism

Product Type : Other, Dual Flush Fitting

Flow Rate : Dual Flush: 3L (Half) / 6L (Full)

Usage & Applications : Toilet Cistern/Flush Tank

INTERNAL FILL VALVES

Minimum Order Quantity : 50 Pieces

Connection : Threaded 1/2 inch inlet

Technology : Floatoperated mechanism

Product Type : Other, Internal Fill Valve

Flow Rate : 68 liters per minute

Usage & Applications : Water tank and toilet cistern filling

FLUSH PIPE HIGH LEVEL

Minimum Order Quantity : 50 Pieces

Connection : Threaded Joint

Technology : Blow Moulded

Product Type : Other, Flush Pipe High Level

Flow Rate : Suitable for standard gravity flush

Usage & Applications : Highlevel flush tank connection to WC (Water Closet)

LLC FITTING

Minimum Order Quantity : 50 Pieces

Connection : Threaded

Technology : Precision Machined

Product Type : Other, LLC Fitting

Flow Rate : Standard/Varies by Size

Usage & Applications : Industrial piping, plumbing, oil and gas application

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS